How to produce cemented carbide

1. Preparation of the mixture: First, mix the refractory metal compound (hard phase) and the bonding metal (binder phase) in a certain proportion to form a powdery mixture. Other components may need to be added during this process, and organic solutions may be used to assist grinding.

2. Forming: In order to ensure the required shape and size of the cemented carbide, the mixture is made into a blank by cold pressing or hot pressing. Cold pressing usually adopts bidirectional pressing or multi-directional pressing to ensure the density uniformity of the blank and avoid the occurrence of defects. Hot pressing is formed in a graphite mold at sintering temperature, and is suitable for the production of large or special-shaped cemented carbide products.

3. Sintering: Sintering of cemented carbide is an important link, which involves processes such as plasticizer removal, degassing and solid-phase sintering. This process is usually carried out in a vacuum sintering furnace at a temperature of approximately 1600℃. Sintering not only includes plasticizer removal, but also includes multiple stages such as solid phase sintering, liquid phase sintering, alloying, densification, and dissolution.

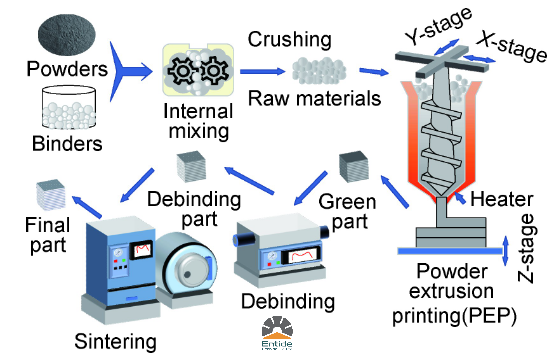

4. Other preparation methods: In addition to the traditional powder metallurgy methods mentioned above, there are other preparation technologies, such as injection molding, extrusion molding, compression molding, hot pressing, hot isostatic pressing, spark plasma sintering, etc. However, these methods may be restricted by the cost of molds and are difficult to deal with complex-shaped cemented carbide products.

5. Surface modification: In order to improve the function and application scope of cemented carbide, methods such as plasma spraying, reactive flame spraying, tungsten inert gas arc melting and laser surface treatment are also used to prepare hard alloys for coating materials and coatings. quality alloy.

6. Application of additive manufacturing technology: With the development of additive manufacturing technology, such as powder bed fusion (PBF), selective laser melting (SLM), electron beam additive manufacturing (EBM), etc., they have been used in the production of cemented carbide.