Why choose carbide bushings?

Carbide bushings have the characteristics of high hardness and high wear resistance. Compared with bushings made of other materials, carbide bushings can reduce the possibility of deformation.

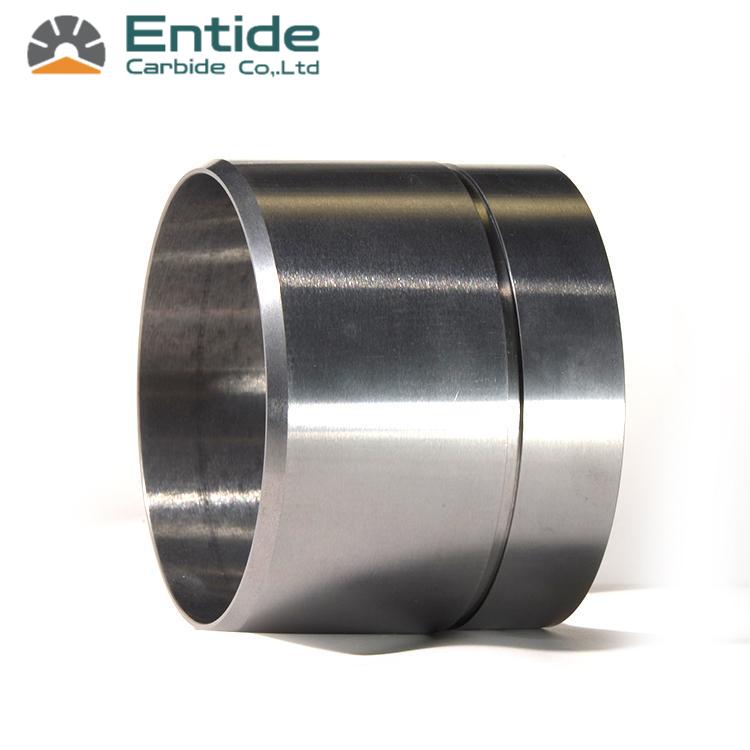

Most of the bushing parts are thin-walled components with uncomplicated structures and relatively high precision requirements. They mainly play the role of positioning and rotation in the product, and bear certain radial and axial forces. The quality of its processing directly affects the function and life of the product. There are bushing parts in almost every product, and their dimensional accuracy and shape accuracy are often affected by severe deformation during processing. To solve this problem, we need to solve the problem fundamentally, use good materials, and ensure the accuracy of the parts.

Carbide bushings have high temperature resistance, corrosion resistance, wear resistance and other properties. They are widely used in modern manufacturing industries, especially core working parts in some special working extreme environments, such as oil and gas, automobiles and ships, and steel mines. Equal-scale industrial production. Under such harsh conditions, in order to prevent the deformation and failure of the bushings, the material of the bushing must be durable and corrosion-resistant, so carbide bushings have become everyone's first choice.

Carbide bushings are one of the main products of Entide Cemented Carbide Co., Ltd. We have advanced processing equipment, diversified production lines, and particularly strong processing capabilities. We also support non-standard customization. You are welcome to come to us with drawings for inquiry.